We are continuing with the rebuild of the X-axis drive system. After a short brake caused by business and leasure trips we are now close to completion of this German “Dauerbaustelle” (permanent building site).

The overall build was a bit lenghty… Before we could start this project we first had to complete the rebuild of our Cazeneuve HBX 360 lathe.

Previously:

- Teil 1 – Start des Umbaus, mit CAD Modellen

- Teil 2 – mit den Aluteilen von André aus der Nähe von Bremen

- Teil 2 1/2 – Herstellung der Spindelhalter

- Teil 3 – Zwischenstand und Herstellung der Lagerblöcke

Preparation

Before Fabian and I could start this exiting “shop-weekend” we had to do some improvements on the power supply of the shop. To date we only had one 16 A CEE socket available and could not work in parallel.

Soon we will have 7 16 A CEE sockets available throughout the shop plus 1 32 A CEE socket for the CNC router. Everything will be split in 5 independent circruits.

Soon we will be showing some more details in a seperate article.

Bearing support

André had to re-do one of the two bearing blocks after feeding the boring head too much. The fit was just too loose. Unfortunately his proposal to bridge the gap with some precision calibre band was turned down (for obvious reasons).

Reordering the stock was not so easy. Surprisingly few online stores have 100 x 100 mm raw steel in stock.

After machining we decided to blue the steel parts for better corrosion protection. Unfortunately the finish turned out a bit flaky – despite swiping the parts equally with acetone to remove any residual oils.

The parts before bluing. All functional faces were milled flat with a milling head, the remaining surfaces received a light shining with the beld sander.

Turned parts

At the same time we manufactured the remaining turning parts on our lathe.

When swapping the morse taper tools we realized that we managed to miss 3 screws during tailstock assembly… Now we know why ejecting the tools was so hard!

In order to improve run-out when machining the other side of the part we used soft jaws. Previous to machining the actual part the soft jaws are bored out with a boring bar to a slightly smaller dimension.

The result: Perfect dimensional stability and a mirror finish.

Our refurbished Cazeneuve earned our respect.

The only thing where the machine did not perform as expected was the thread cutting function. Sometimes the automatic pick up function of the lathe did not engage and ended up destroying the previously machined threads. We need to have a look at this problem in more detail later…

Overview

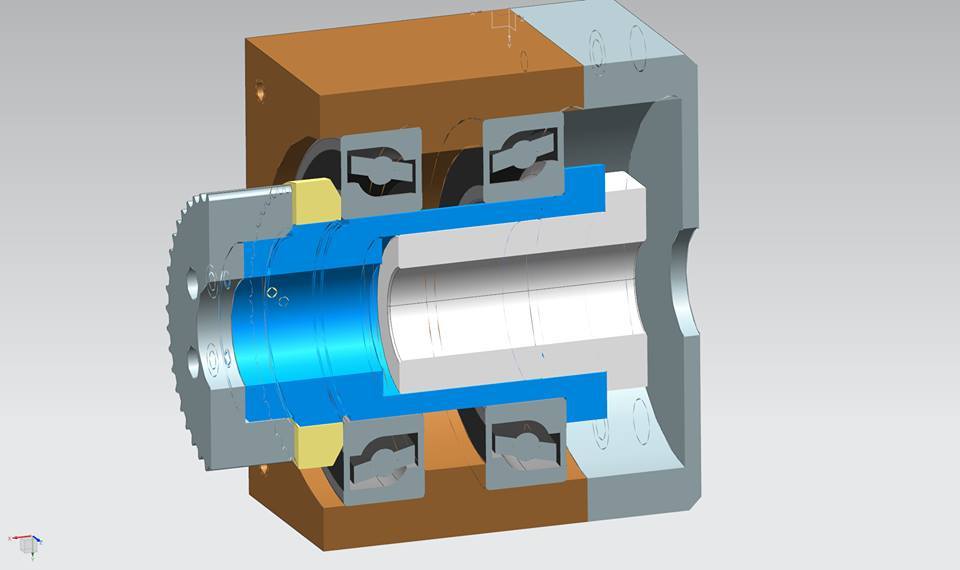

Left: CAD model, right: finished parts. On both sides the parts look relatively small – but trust me, they are large and heavy!

All components at a glance:

- Belt housing with motor mount and motor

- Lid for belt housing

- Bearing support with mounting adaptor

- Cartridge with belt pulley

- Cartridge, bearing and belt pulley

Next time..

The only parts still missing are the mounting / clamping plates for the ball screws. We already ordered the stock and will start machining the parts shortly.

No Responses